There are plenty of reasons to consider adding advertising to your car, truck, trailer, or even your bus, boat, motorcycle, or aircraft!

According to a study by 3M, fleet graphics are the most cost-effective outdoor advertising medium available, delivering greater value on a cost-per-thousand impressions basis than television, magazines, newspapers, prime-time television, radio, and outdoor billboards!

Another study found that vehicle lettering, car wraps, and similar graphics are as effective as they are economical. Their research showed that:

97% of survey respondents recalled the vehicle graphic on the truck.

98% thought the vehicle ads created a positive image of the advertiser.

96% believed fleet graphics had more impact than billboards.

One of the attractive features of vehicle graphics is their flexibility. They allow you to choose from a range of options depending on your business needs and marketing budget. Consider the following three primary vehicle graphic options:

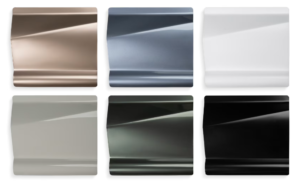

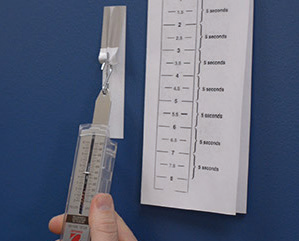

- Vehicle Lettering: This is the simplest and most economical choice. Vinyl letters and numerals can be applied to your vehicle. Use this option if your vehicles are not the primary promotional medium for your business but complement other advertising methods well. Most marketers use vehicle lettering to spell out their company name, slogan, phone number, address, and web address. These letters can be designed, fabricated, and installed quickly. They are often placed over side and rear windows for good contrast and excellent readability.

- Partial Vehicle Wraps: These wraps cover part of your vehicle with a promotional message. They offer a higher visual impact than vehicle lettering but are less expensive than full wraps. They are a great option if your vehicles are extensively used for sales, service, or delivery calls.

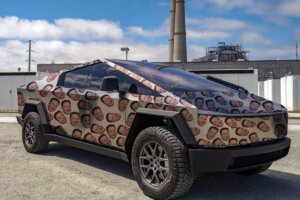

- Full Vehicle Wraps: These wraps deliver maximum visual impact by covering all four sides of your vehicle, and may even extend to the roof and bumpers. They are more expensive but are still less costly than a custom paint job. Full wraps are often used by businesses whose vehicles are their main option for promotions, such as carpet cleaning, HVAC, and florist vans. They can also provide a protective layer to your vehicle’s finish. Full vehicle wraps are also readily removable, making them suitable for leased vehicles or promotional purposes during events. Some companies even extend their designs to side and rear windows using perforated window graphics for additional visibility.

In conclusion, vehicle graphics offer a cost-effective and impactful way to promote your business, with options to suit various budgets and marketing needs.