Exploring the 3M™ Wrap Film Series 2080: A Revolution in Car Wraps

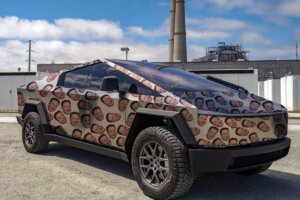

Car enthusiasts and professional detailers alike know that transforming the look of a vehicle can be both an art and a science. The 3M™ Wrap Film Series 2080 offers an innovative solution that combines cutting-edge technology with a vibrant palette of colors, enabling users to achieve stunning visual results with ease. In this blog post, we’ll delve into the unique features of the 3M™ Wrap Film Series 2080 and explore the extensive range of colors available to suit every style and preference.

Why Choose 3M™ Wrap Film Series 2080?

3M has long been a leader in the automotive film industry, known for its commitment to quality and innovation. The Wrap Film Series 2080 is no exception, boasting several key benefits:

- Superior Conformability and Flexibility

- The 3M™ Wrap Film Series 2080 is engineered to conform to the most complex curves and contours of a vehicle, ensuring a smooth and seamless application. This makes it ideal for intricate designs and detailed work.

- Durability and Longevity

- Designed to withstand the elements, the 2080 series offers excellent resistance to UV rays, moisture, and abrasions. This ensures that your car’s new look will stay vibrant and intact for years to come.

- Innovative Protective Layer

- One of the standout features of the 2080 series is its unique protective film layer, which guards against scratches and handling marks during installation. This layer can be easily removed after application, revealing a pristine finish.

- Easy Installation and Removal

- Thanks to 3M’s advanced adhesive technology, the Wrap Film Series 2080 allows for repositioning during application, reducing the risk of bubbles and wrinkles. Additionally, it can be removed cleanly without damaging the underlying paint, making it a great option for both temporary and permanent applications.

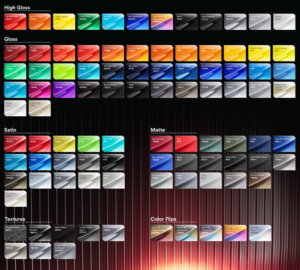

A Kaleidoscope of Colors

One of the most exciting aspects of the 3M™ Wrap Film Series 2080 is the extensive range of colors and finishes available. Whether you’re looking to make a bold statement or add a subtle touch of elegance, there’s a color for every taste. Here are some of the standout options:

- Gloss Colors

- Gloss Blue Fire: A vibrant and eye-catching shade that adds a pop of color.

- Gloss Wicked: A deep, mysterious purple that commands attention.

- Gloss White Gold Sparkle: Adds a touch of shimmer and sophistication.

- Matte Colors

- Matte Black: A classic choice for a sleek, modern look.

- Matte Military Green: Perfect for an edgy, rugged appearance.

- Matte Indigo: A unique blue hue that offers a softer alternative to gloss finishes.

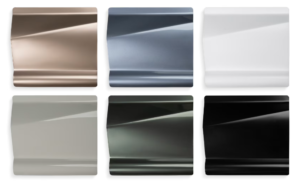

- Satin Colors

- Satin Pearl White: A luxurious finish that exudes elegance.

- Satin Key West: A calming, tropical blue-green that brings a sense of tranquility.

- Satin Smoldering Red: A rich, fiery red that makes a bold statement.

- Textured and Special Effects

- Carbon Fiber Black: Offers a high-tech, textured look that mimics real carbon fiber.

- Brushed Steel: Provides a metallic, industrial aesthetic.

- Shadow Military Green: Combines a unique texture with a subdued, military-inspired color.

Conclusion

The 3M™ Wrap Film Series 2080 stands out as a premier choice for car wraps, offering unparalleled quality, durability, and ease of use. With a broad spectrum of colors and finishes to choose from, you can customize your vehicle to reflect your personal style and make a lasting impression on the road. Whether you’re a professional installer or a DIY enthusiast, the 2080 series promises to deliver exceptional results that will turn heads and inspire awe.

Explore the endless possibilities with the 3M™ Wrap Film Series 2080 and discover the perfect hue for your next automotive masterpiece.